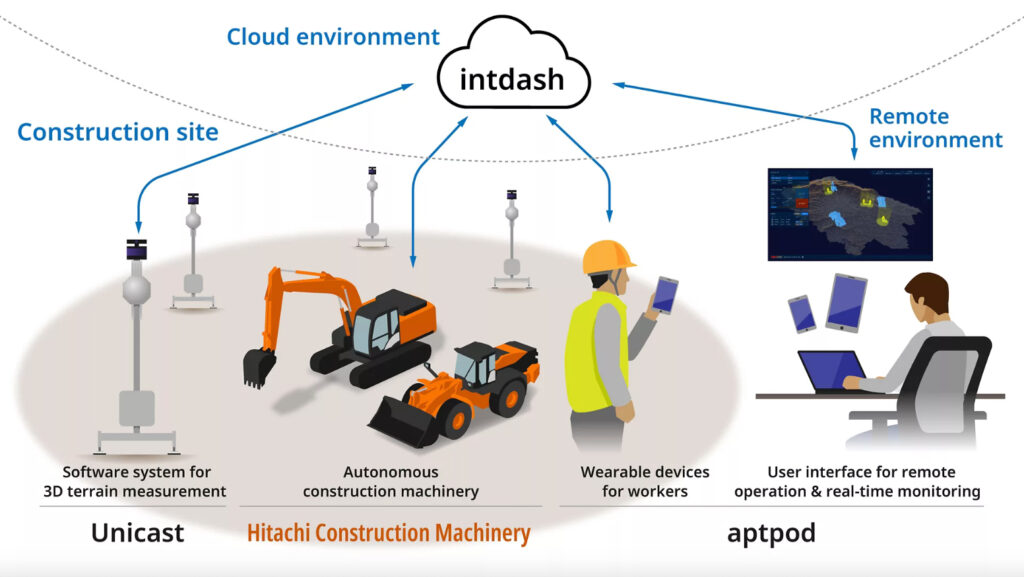

Hitachi Construction Machinery has developed a real-time digital twin platform in cooperation with aptpod, a provider of fast data and big data solutions, and Unicast, a provider of IT professional services and robotic solutions. The platform reproduces the construction site in a virtual world from data collected in real time, enabling the management of construction progress and the operation of autonomous construction machinery from a remote location on the Internet.

In recent years, labor shortages have become an issue in the construction industry due to the decreasing birthrate and aging population. Customers have high expectations that autonomous construction machinery will become one solution to that problem. To meet these expectations, Hitachi aims to realize construction sites in which people and machinery work in a coordinated manner to balance safety and productivity through “collaborative safety” by mutually sharing information about the people, machinery, and site environment. Specifically, people would be alerted to pay attention and construction machinery would be controlled based on information collected by the machinery and sensing systems to carry out highly productive construction while guiding the overall site in a safe direction.

To realize this type of construction, Hitachi developed the ZCORE system platform for autonomous construction machinery in August 2020. In addition, the company invested in and signed a business alliance agreement with aptpod in May 2023 to promote the development of a digital twin system that visualizes an entire construction site and autonomously operates construction machinery.

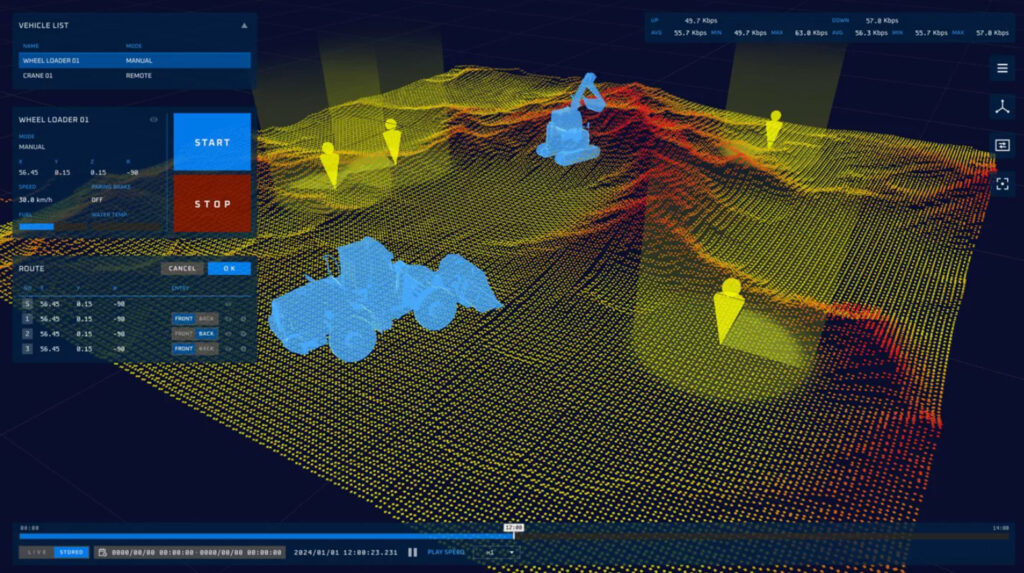

This platform can reproduce real-time real-world construction sites in the virtual world, including various information such as the location and operational information of construction machinery, the location and biometric information of workers, terrain changes due to the progress of work, and other construction site conditions. This will enable adjustments to be made to the work details of individuals and the control of multiple pieces of construction machinery working on site with low latency on the Internet from a remote location to realize construction sites where people and machinery coexist with a high degree of safety.

In the development of this platform, Hitachi Construction Machinery was in charge of providing autonomous construction machinery (hydraulic excavators and wheel loaders) and defining the requirements for reproducing a construction site as a digital twin. Aptpod developed the cloud system for data collection based on its “intdash” high-speed IoT platform and the mobile and PC user interface used by the workers, and Unicast developed the software for converting the terrain of a construction site into 3D data based on data obtained from LiDAR. The ability of the technologies from aptpod and Unicast to transmit and process large volumes of constantly changing data enables the construction of a highly real-time digital twin. Going forward, the companies aim to realize collaborative safety which includes advanced autonomous construction machinery and improved site safety and productivity through repeated verification tests for practical application.

Hitachi Construction Machinery is also planning to hold an exhibition related to this platform at the 6th Construction & Survey Productivity Improvement EXPO (CSPI-EXPO) to be held from May 22 to 24, 2024, at Makuhari Messe in Chiba Prefecture, Japan.

Source: Hitachi Construction Machinery

Copyright 2021 All rights reserved.

Copyright 2021 All rights reserved.